About Us

- Home

- About Us

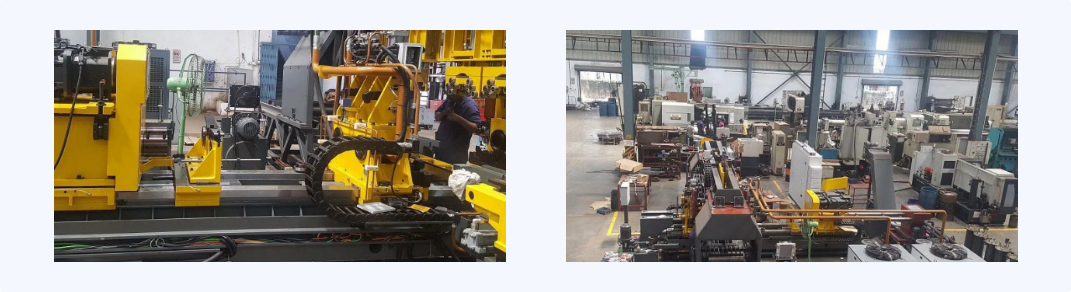

We make highly precise multi-axes machineries.

For more than 25 years, Patel Machinery has been the leading Indian Manufacturer of highly precise multi-axes machineries. We progressively enhanced the machine capabilities to meet the market need. We are well experienced team of Engineers having insight knowledge of machines and control over it to guarantee the delivery of high quality and precision machines to customers.

We are also involved in sharing our expertise and vast exposure to formulate and enhance the production planning with latest technologies.

Creating Your Startup Business

We help you see the world differently, discover opportunities you may never have imagined and achieve results that bridge what is with what can be.

Accounting & Finance

A great corporate strategy combines five elements: a bold yet realistic ambition, a carefully considered portfolio.

Management Skills

A great corporate strategy combines five elements: a bold yet realistic ambition, a carefully considered portfolio.

Business Planning

A great corporate strategy combines five elements: a bold yet realistic ambition, a carefully considered portfolio.

Global Reach with Local Understanding

In healthy companies, changing directions or launching new projects means combining underlying strengths and capacities with new.

marketing analysis

finance strategy

business innovation

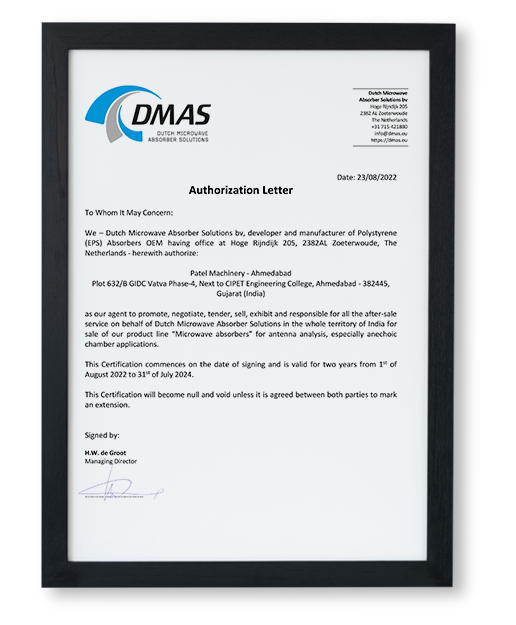

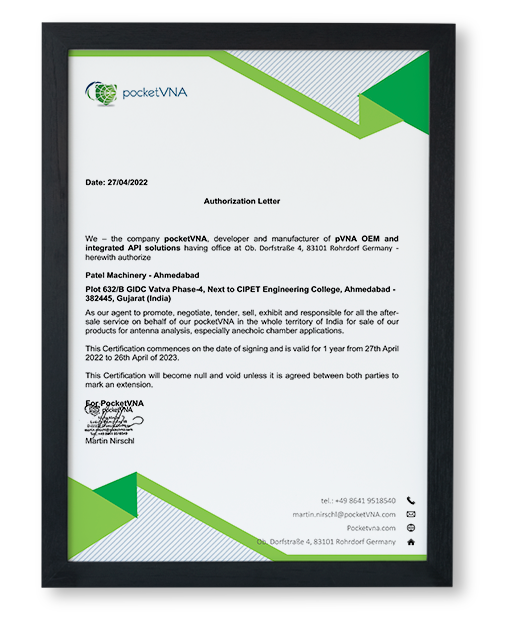

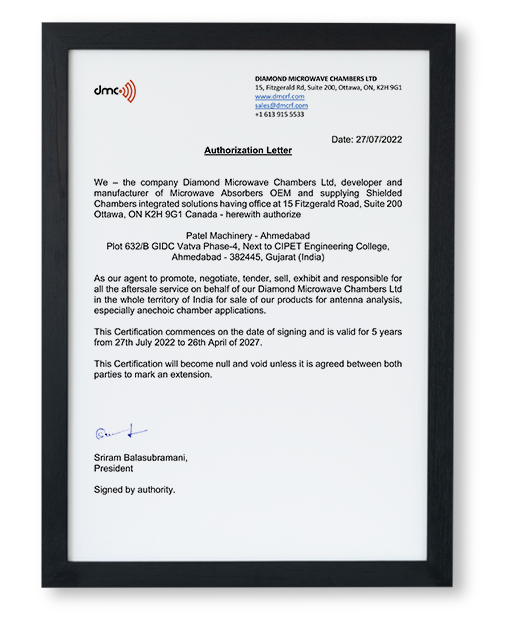

Joined hands with world leaders

we’ve tied up with industry renowned business names, to provide superior technology and to see the world differently.

Our Skilled Leaders

We help you see the world differently, discover opportunities you may never have imagined and achieve results that bridge what is with what can be.

Pretigious Projects Completed by Patel Machinery

For more than 25 years, Patel Machinery has been the leading Indian Manufacturer of highly precise multi-axes machinery.

- We designed and developed PLC with Modbus Communication Protocol.

- Started Developing Stepper Motor Design work.

- Start importing Refurbished CNC machines from Europe, USA, and Japan.

- Become a dealer for FAGOR Automation Spain for linear and rotary encoders and CNC systems.

- We Become Member for Japanese Popular communication protocol called “Mecatrolink”.

- Opened branch office in Germany named “Patel Machinery GmbH”.

- In year 2006 we become Ether CAT Technology Group member.

- First motion controller developed with Digital Protocol EtherCAT in support with German company “Modusoft GmbH”.

- Started manufacturing of Special purpose customized machineries.

- Supply Custom Design machinery for SS Seamless pipe manufacturer for “Jindal Saw Limited” & “Ratnamani Metals And Tubes”.

- Developed Involute Generation Program Using Our Designed CNC Controller for Gear Teeth Grinding machine and successfully Installed In India.

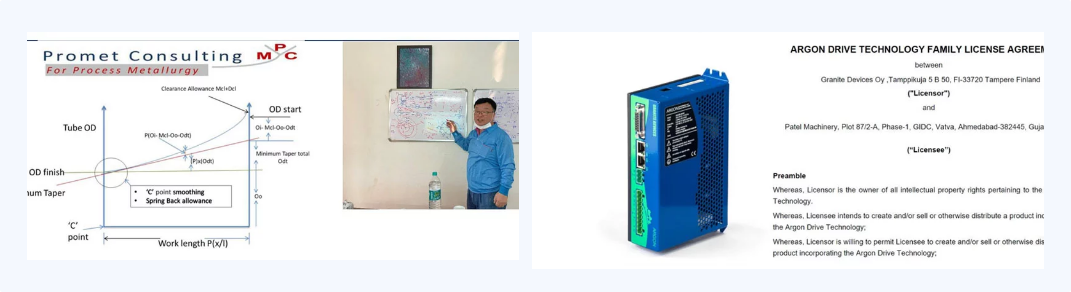

- Started working in the field of metallurgical science and developed different processes in-house for material treatment.

- Started design and development of SERVO Frequency drive in support of “GRANITE Devices” Finland.

- Release the First Open Frame servo drive and start using in-house projects.

- Started training for Pilger Tooling design with Korean and British Companies.

- Manufacture Special purpose Taper parabolic Shaft machining without rotation (first time in India) we achieve an accuracy of 0.01 mm in the full length of 1000 mm.

- It is one of the pioneer development in India through Indigenous efforts.

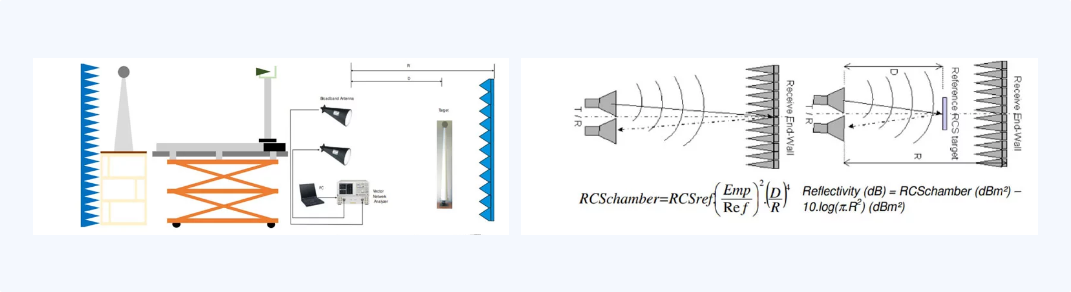

Chamber Reflectivity Measurement using RCS Method

- Radar Cross Section is defined as the area that can be perfectly detected back when electromagnetic waves were transmitted from its source to its target place. RCS measurement method techniques are used to define the reflection loss performance of pyramidal microwave absorbers mounted on a wall.

- From the linear “Emp” and “Ref” measured data, one computes the RCS of the receiving wall which is also the anechoic Chamber RCS, and the Absorber’s reflectivity from the following formulas.

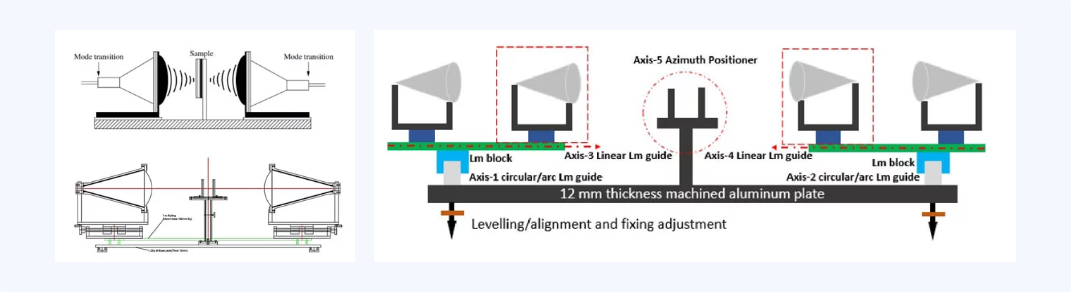

Spot Focusing Antenna Free Space Test Setup

- The electromagnetic characterization of composite sheet is required to find their effectiveness as an electromagnetic absorber. The electromagnetic characterization is facilitated here by measuring the complex permittivity of the Afabricated absorber sheet using a free-space measurement setup.

- The experimental free-space measurement setup consists of a pair of focusing horn lens transmitting and receiving antenna which are mounted on a large aluminum turntable. The spot-focusing horn lens antennas consist of two equal planoconvex dielectric lenses mounted back to back in a conical horn antenna, with one planoconvex lens giving an electromagnetic plane wave and the other planoconvex lens focusing the electromagnetic radiation at the focus.

Precision Multi-axis Heavy Duty Antenna Positioner

We offer an expanded line of positioning systems designed to satisfy the most demanding applications in antenna measurement and tracking of satellites.

Our closed-loop feedback system provides precise speed and positioning capability. Digital controllers and positioners have been following the military standards for environmental testing.

The positioning system will be used in military and civilian systems and it will be successfully installed in ground-based, shipboard, and airborne applications.

The 4-axe DUT Positioner is designed to satisfy the most

demanding applications in antenna measurement and tracking of satellites. The closed-loop feedback system provides precise speed and positioning capability.

Features

- Precise Positioning System

- Precision Slewing Bearing and Drive

- Standard Absolute Encoders

- Multi-level Electro-Mechanical Braking System

- Limit Switches to Limit the Range of Motion with Speed Control

- Controller and PC-based Measurement Workstation

- Integration of Motion Controller with Automated

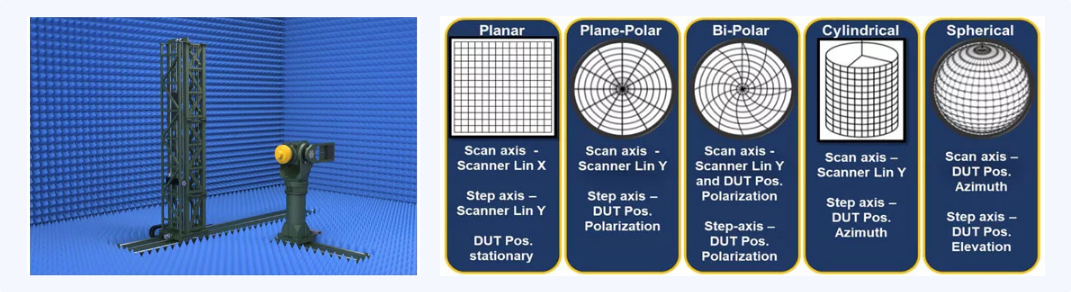

Inverted T-Scanner for Near-Field Antenna Measurement

A Planar Near-Field Measurement Scanner is an ideal system for measuring medium and High Gain Antennas (>15 dBi), making it suitable for testing feeds and arrays of reflector antennas. The Scanner is constructed in such a way that it can be easy to assemble and align accurately and can be quickly dismantled for relocation or storage.

The system interfaces with a wide variety of RF instruments, capable of measuring amplitude and phase patterns from L-band to mm-Wave bands (1 – 200 GHz). Measured data can be processed for far-field antenna radiation patterns or holographic aperture distribution.

A single data set provides a complete characterization of the antenna’s gain, side lobes structure, beam pointing, cross-polarization, and other antenna parameters.

Features

- Highly Accurate Planarity

- Controller and PC-based Measurement Workstation

- Installation Tool Kit

- L-Band to mm-Wave Measurements

- X-Y Servo Motor Drive System

- Motor Drive Electronics

- Cylindrical and Spherical Scanning Optional

- Antenna Measurement Software

- Precision Rack and Pinion Drive

Near-Feild Antenna Measurement

The Space & Defence Engineering Section of Patel Machinery developed the most accurate Planar Near-Field scanner systems to cater to high-frequency measurements up to 200 GHz. It can also be configured in a horizontal scan plane to cater to the characterization of large-size, bulky in weight & gravitational sensitive antennas. We have a wide range of NF scanners available in sizes with a travel range of 0.5m to 30m.

The developed scanners are four axes assemblies having a Polarization positioner to support the waveguide probe, linear Z-slide to manage the distance between DUT and probe, linear Y-slide (vertical axis in case of the vertical scanner), and precision linear X-slide (floor slide).

It’s a lightweight vertical structure with high rigidity travels and a load balancing mechanism to avoid deflection due to gravity.

The scanners are fitted with a drive system based on customer applications.

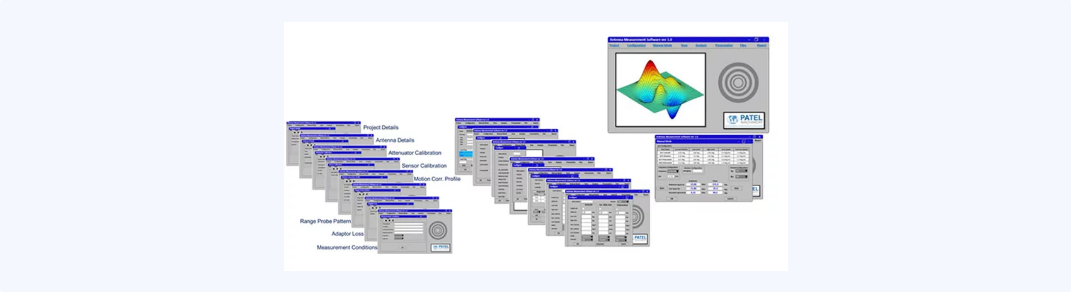

Antenna Measurement Software

Antenna Measurement Software (AMS) developed by Patel Machinery satisfies the most demanding applications of Antenna, Radom, and RCS measurements.

It gives quick verification of defined test configurations. Provide feasibility to select any configuration and move any axis of a positioner.

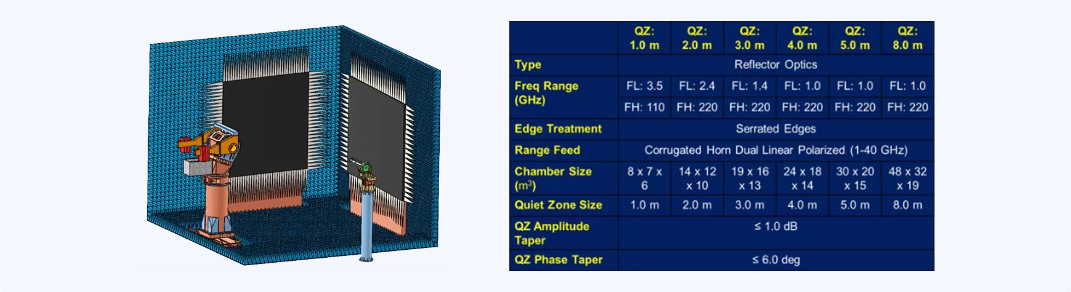

Dual Reflector Compact Antenna Test Range

The far-field antenna measurement offers a quick estimation of antenna performance.

The traditional far-field concept demands a large separation between transmit and receive sides, which is practically impossible for large size of antenna at higher frequencies.

The reflector-based compact antenna range offers all the advantages of far-field and simulate a far-field equivalent environment in a very compact indoor test chamber.